3D HOLLOW FIBER: A SIGNIFICANTLY BETTER WAY TO CULTURE CELLS

Modeled after the mammalian circulatory system, Hollow Fiber Bioreactors (HFBRs) offer the most in-vivo like manner to grow cells in any laboratory.

KEY ADVANTAGES OF 3D CELL CULTURE

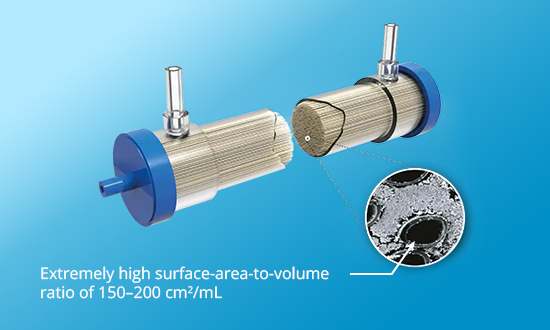

EXTREMELY HIGH SURFACE-AREA-TO-VOLUME RATIO OF 150–200 CM2/ML WITHIN A SINGLE CARTRIDGE

The small diameter of the fibers (200 μM) generates an extremely high surface-area-to-volume ratio of 150-200 cm2/mL within a cartridge. The exchange of nutrients and waste is high enough to support cell densities of 1–2 x 108 /mL, approaching in-vivo tissue-like densities. This high cell density allows for the simplification of the cell culture medium, with differences in medium formulation performance mitigated by the cells’ own secreted factors. In fact, the more complex and more expensive a cell culture medium is, the less effective it is in a hollow fiber cell culture environment.

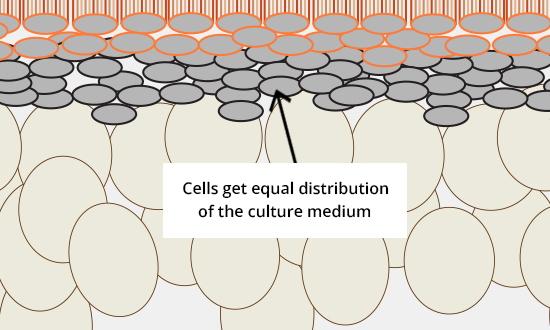

CELLS ARE CONTINUOUSLY BOUND TO A POROUS SUPPORT

Cells bound to a porous support do not require splitting or passaging, and nutrients are delivered upwards from the bottom layer of cells.

This allows HFBR cultures to maintain viability and productivity in a postconfluent manner for extended periods of time. Furthermore, cells in an HFBR are not subject to shear. Necrotic cells do not become apoptotic and do not release significant cytoplasmic proteins or DNA into the harvested product. This provides a cleaner culture environment for more accurate culture parameter monitoring, and a harvest that is simplified and easier to handle for downstream assays and purification.

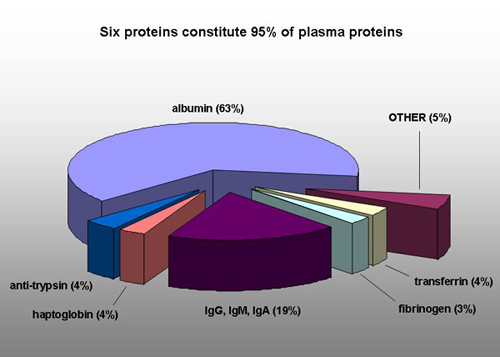

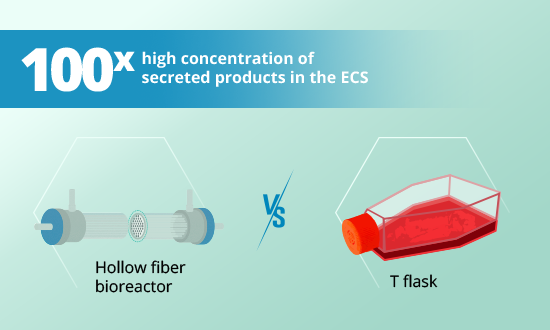

UP TO 100X HIGHER CONCENTRATION OF SECRETED PRODUCTS RETAINED WITHIN THE EXTRACAPILLARY SPACE (ECS)

By altering the Controlled Molecular Weight Cut-Off (MWCO), secreted products can be retained within the ECS to concentrations up to 100 times higher than in standard cultures. The effects of cytokines on the cells can also be controlled. Secreted recombinant proteins can be selectively retained and concentrated while cytokines and other factors that facilitate cell-to-cell interactions can be concentrated. Small molecule drugs can be easily exchanged across the fiber and rapidly reach equilibrium, while larger bacteria and cells are retained.

EQUAL DISTRIBUTION OF CULTURE MEDIUM TO EACH CELL IN THE CARTRIDGE

For cells grown on nonporous plastic dishes, nutrients in the flask culture are delivered via a top-down approach, meaning that the bottom layers can become deprived of nutrients. As cells need to be passaged every 2-5 days, this is disruptive and results in the generation of huge amounts of plastic waste.

On the other hand, HFBRs contain thousands of semipermeable hollow fibers in a parallel array within a tubular housing fitted with inlet and outlet ports. The fiber bundles are sealed with a potting system at each end so that any culture medium entering the ends of the cartridge must flow through the interior of the fibers. This ensures that the culture medium is equally distributed to each cell in the cartridge.

With the advances in 3D Hollow Fiber Cell Culture methods, conventional cell culture techniques such as T flasks and roller bottles are not the most physiologically relevant way to grow cells or the most optimal way to harvest biologics for production.

Check out the comparison between 3D Hollow Fiber and 2D cell culture methods here.